Turbo-Chem recommends pumping SwelLCM® @ 10 – 12.5 ppb. (at any weight) ahead of high fluid loss/high solid squeeze applications and/or cement jobs. The SwelLCM® should be mixed at ½ the volume of the squeeze and/or cement pill to be pumped behind it.

Can be utilized as a Pre-Cement application to avoid multiple failed cement operations.

Vital in stopping losses in cavernous formations which normally would require cementing or plug and abandonment.

Eliminates the risk of sidetracking (which can occur with cementing).

Effective at both low and high wellbore temperatures.

Easily mixed through the hopper.

Can be used in drilling or working over cased holes for sealing leaks and perforations.

Less costly alternative to pumping multiple LCM pills and/or cement.

Very low concentrations are required.

Proper PPE should be worn while handling this product. Minimize dust exposure. Please review the SDS before using.

SwelLCM® is available in 10 lb. pails, 32 pails/pallet.

An empty isolated mixing tank is ideal.

SwelLCM® should only be mixed before pumping. Not recommended to be mixed days ahead.

Mix water must be adjusted and maintained at 2-3 pH while mixing.

SwelLCM® should be agitated for 30 minutes to an hour for proper polymerization to occur.

Barite should be added after all the SwelLCM® pails are mixed (while maintaining a pH of 4 or below).

1. Clean the mixing pit and lines thoroughly leaving no residual mud in the pit or the lines.

2. Add 49 bbls of freshwater to the mixing pit.

3. Adjust the pH of the freshwater to 3-4 pH using SwelLCM® Activator.

4. Add 63 pails of SwelLCM® to the 3-4 pH mix-water and allow agitation until homogenous.

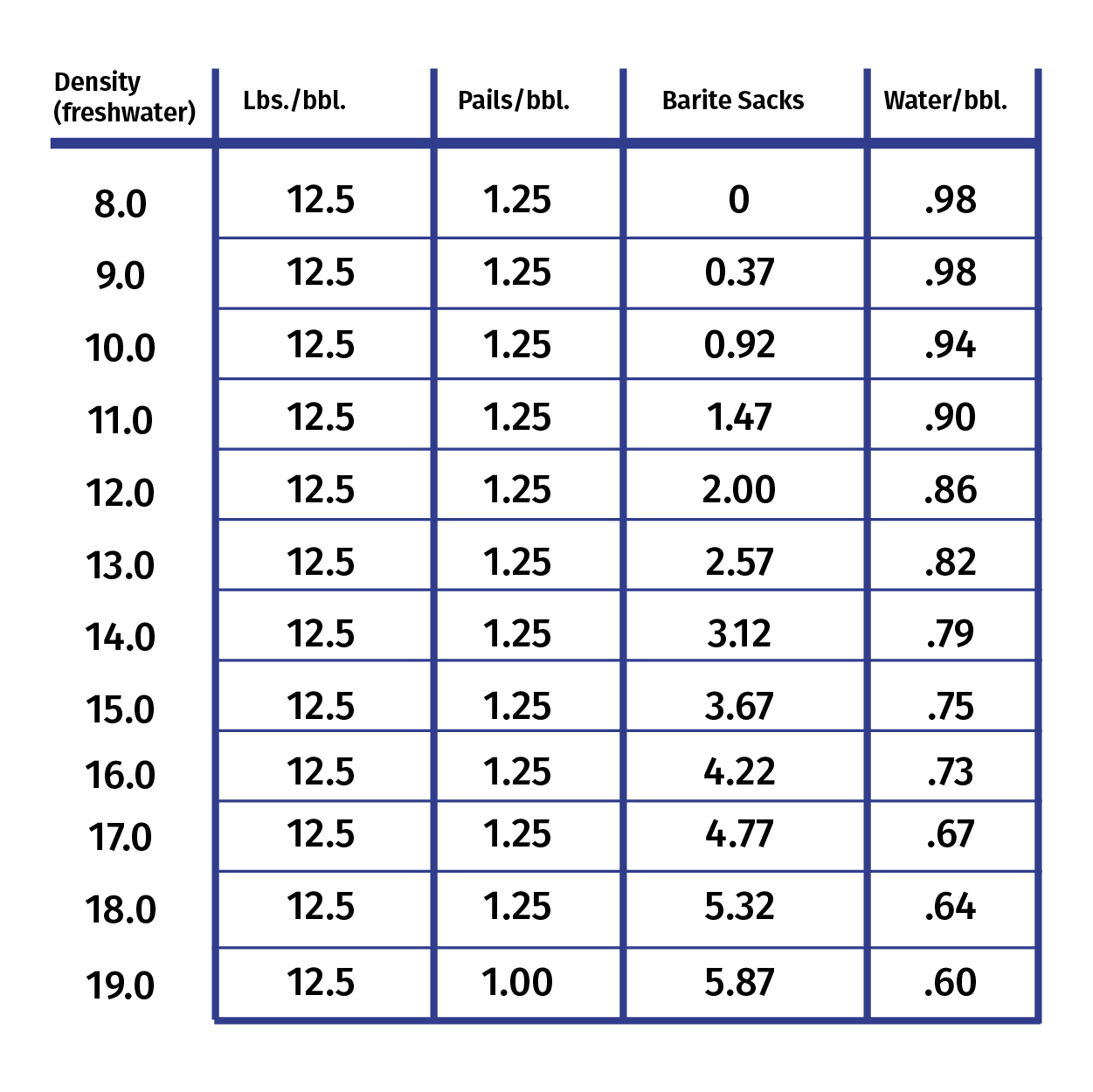

5. Add barite, if needed, to reach the desired slurry weight while maintaining 3-4 pH.

6. Mix the entire slurry until homogenous, then pump the SwelLCM® slurry into the drill pipe, followed by 3 bbls of system mud, then begin the mixing procedure for EZ Squeeze® and/or Cement.

Turbo-Chem International develops high-quality, patented products that identify and address the specific needs of rig operators for drilling, completions and production operations.