Turbo-Chem recommends using EZ Squeeze® to remediate partial to massive losses in the open hole and/or sealing perforations in the cased hole. Mixing and pumping procedures will be provided by Turbo-Chem using well data at the time of loss.

Can be utilized as a Pre-Cement application to avoid multiple failed cement operations.

Can be pumped through downhole tools up to 100 ppb.

Eliminates the risk of sidetracking (which can occur with cementing).

Effective at both low and high wellbore temperatures.

Compatible mixing in all drilling fluids.

Less costly alternative to pumping multiple LCM pills and/or cement.

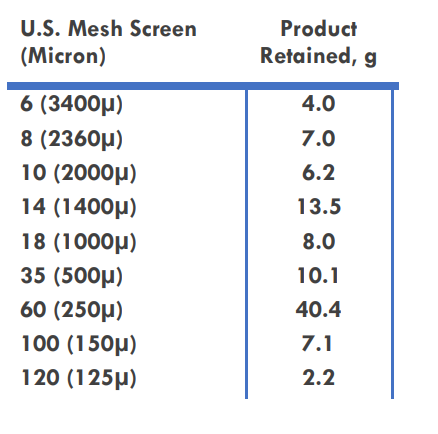

Tailored particle size range optimizes the sealing capabilities of multi-sized fractures and reduces effective response time to whole mud losses.

Proper PPE should be worn while handling this product. Minimize dust exposure. Please review the SDS before using.

EZ Squeeze® is available in 25 lb. sacks, 50 sacks/pallet.

An empty isolated mixing tank is ideal.

EZ Squeeze® can be pre-mixed at any time. If no barite is added, the EZ Squeeze® slurry can stay in solution (as long as it’s hydrated) for weeks before pumping. Low sheer mixing for 15-30 minutes per day is recommended.

Patience, time and correct placement of the slurry are necessary for a successful EZ Squeeze® job.

Effective at both low and high wellbore temperatures.

If a slurry has been weighted by accident, add additional EZ Squeeze® to prevent future barite settling.

Ideally, enough EZ Squeeze® should be mixed to cover all potential loss zones and enough excess slurry to execute a hesitation.

1. Clean the mixing pit and lines thoroughly leaving no residual mud in the pit or the lines.

2. Add 77 bbls of freshwater, 4 pails of Turbo-Defoamer and 12 pails of EZ Thin to the mixing pit.

3. Add 400 sacks of EZ Squeeze® to the mixing pit and allow agitation until homogenous.

4. Add Barite, if needed, to achieve the desired slurry weight.

5. With the bit @ a depth at which all of the slurry can exit the bit and 20 bbls of EZ Squeeze® are in the formation, pump the 100 bbls of E Z Squeeze® slurry to the drill pipe with rig pumps at 3-5 bpm to the bit.

6. As the EZ-Squeeze® reaches the bit, begin bull-heading the slurry out of the bit until all of the 20 bbls of EZ Squeeze® are in the formation of concern. If at any time a significant increase in pressure is achieved before bull-heading the recommended volumes into the formation of concern, discontinue pumping, open hydril, and pump the remaining EZ Squeeze® slurry as a balanced pill. POOH to above the slurry inside the casing and circulate an additional 10 bbls of system mud to ensure the DP and BHA are clear of any remaining slurry. Turbo-Chem never recommends leaving slurry inside the DP with a bit, with jets or any tools. Shut down for 1 hour and monitor well.

7. Before beginning hesitations, check the fluid level on the backside. If any fluid should be required to fill, obtain accurate fluid volumes required to fill to know the exact location and volume of slurry remaining. Begin hesitations by pumping 5 bbls @ ½ to 1 bpm, every 30 – 45 minutes, until desired pressure is achieved. If no pressure is obtained upon squeezing half of the remaining EZ Squeeze® volume (50 bbls) into the formation, discontinue pumping and wait one hour. Resume hesitations by pumping 3 bbls @ ¼ – ¾ bpm until the desired pressure is achieved or the tail end of the EZ Squeeze® slurry is 3 bbls above the zone of concern, begin a 4-hour wait.

Turbo-Chem International develops high-quality, patented products that identify and address the specific needs of rig operators for drilling, completions and production operations.